Taking responsibility.

Shaping the future.

Climatehandler

Hessian companies are increasingly making their processes more sustainable and thus actively contributing to climate protection. In the video, Sascha Korupp shows how innovative measures not only improve the CO2 balance, but also strengthen competitiveness.

Circular economy

Our castings offer the advantage of a closed cycle in which material is efficiently recycled and reused again and again. This reduces resource consumption and promotes sustainable production, which is both environmentally and economically beneficial.

Conserving resources

Precise use of raw materials reduces waste and minimizes resource consumption in the long term. This strategy protects the environment by reducing pollution and contributing to the long-term sustainability of resources.

Energy efficiency

For us, energy efficiency is the key to sustainable success. With our solutions, we not only reduce our own energy consumption, but also help our customers to reduce their energy costs and improve their environmental footprint.

Sustainable supply chain

Our sustainable supply chain is based on a regional focus that enables us to reduce our environmental impact while responding flexibly to your needs. Through local partnerships, we optimize our processes and strengthen the regional economy.

Climate action at

Herborner Pumpentechnik

Energy efficiency and climate protection

Energy efficiency and climate protection are key issues for a sustainable future. Companies have a responsibility to use innovative measures to make their processes more efficient and environmentally friendly.

Energy efficiency and climate protection are topics that have become increasingly important in the economy in recent years. More and more Hessian companies are making their processes increasingly efficient and sustainable. Economic and ecological goals are not mutually exclusive, but go hand in hand. After all, resource-efficient production is not only good for the climate, but also contributes to a company's competitiveness. One company that is already setting a good example is Herborner Pumpentechnik GmbH & Co KG. Thanks to the targeted use of renewable energies by means of photovoltaics, new melting furnaces and thermal sand processing, production is now much more efficient. The result speaks for itself: Herborner Pumpentechnik saves more than 600,000 kilograms of CO2 every year and thus makes a significant contribution to climate protection. The conversion was funded by the state of Hesse as part of the PIUS-Invest program, which is financed by the Integrated Climate Protection Plan, among other things, and covers almost a fifth of the investment costs.

In the video, Sascha Korupp explains the responsibility of entrepreneurs and shows us why every company must make an individual contribution to a climate-friendly future.

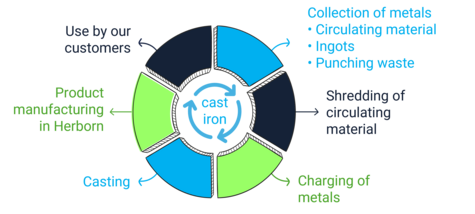

Circular economy

A core principle of our actions

In a world that is increasingly characterized by resource scarcity and environmental pollution, we rely on the circular economy as a central element of our business activities. For us, the circular economy is more than just a trend - it is the key to a sustainable future.

Gray cast iron: sustainability through reuse

Gray cast iron is a material that has long been indispensable in various industries. However, what makes this material particularly valuable is its excellent recyclability. Old cast iron parts can be reused without any loss of quality, which enables us to significantly reduce the amount of raw materials required and minimize waste. By using recycled gray cast iron, we are actively helping to conserve natural resources and reduce CO2 emissions. Every recycled ton of gray cast iron is a step towards more sustainable and responsible production.

Our commitment to a sustainable future

For us, the circular economy is not just an obligation, but a conviction. We develop and manufacture our products in such a way that they can be used for as long as possible, are easy to repair and can be returned to the production cycle at the end of their service life. By focusing on the reuse and recycling of gray cast iron, we show that industry and sustainability can go hand in hand. We are proud to make an active contribution to conserving resources and reducing environmental impact.

Together we are shaping the future - in a resource-saving, efficient and sustainable way.

Resource conservation

Sustainability right from the start

For us, conserving resources starts with the design. We develop our pumps and components in such a way that they offer maximum efficiency and durability. This approach not only reduces the consumption of raw materials, but also waste in production.

Long-lasting products, less waste

Our products are designed for a long service life, which means they need to be replaced less frequently. This reduces the need for new resources and actively contributes to reducing waste.

Our contribution to sustainability

With a focus on resource-conserving design and durable products, we are committed to a sustainable future. Less scrap, less waste - but more efficiency and quality.

Conserving resources is a central component of our production strategy. By using the latest technologies and state-of-the-art machining centers, we optimize material consumption and minimize waste. Our advanced machines enable precise machining, which leads to a significant reduction in waste. With precise control systems and automated processes, we ensure that every resource is used efficiently. Continuous quality control, supported by digital tools, ensures that we use materials optimally and keep waste to a minimum. We also use energy-efficient machines and recycling methods to reduce energy consumption and recycle leftover materials sustainably. These innovative approaches not only improve our production processes, but also actively contribute to environmental protection and reduce our operating costs.

Dardan Ejupi, Head of Mechanical Production

Energy efficiency

A principle that drives us

Energy efficiency is not just a buzzword for us, but a central component of our corporate philosophy. We rely on state-of-the-art technologies and a sophisticated energy management system to continuously optimize energy consumption in our production processes.

State-of-the-art technologies for maximum efficiency

By using an induction furnace and inductive ladle preheating in the foundry, we have significantly reduced our energy consumption. These innovative measures enable us to work more efficiently and reduce CO2 emissions at the same time. Our aim is to minimize energy consumption and implement sustainable solutions in all areas of our company.

Energy savings for our customers too

However, our responsibility does not end with our company. The pumps we have developed are also designed to ensure considerable energy savings for our customers. Thanks to their high efficiency, they help to reduce energy consumption in a wide range of applications and thus cut operating costs.

Sustainability through efficiency

With our commitment to energy efficiency, we are not only committed to climate protection, but also to long-term economic efficiency - for us and for our customers. Less energy consumption means lower costs and a smaller ecological footprint. This is our contribution to a sustainable future.

herbornerX.neo:

Energy efficiency in a nutshell

-

Lower energy consumption:

-

Optimized hydraulic design:

-

Innovative motor technology:

-

Sustainable solution:

Reduces the ecological footprint of your system. -

Future-proof:

Meets the highest energy efficiency standards for a green future

Sustainable supply chain

Regional and responsive

Our sustainable supply chain is strongly focused on regional partnerships. By purchasing from local suppliers, we can not only minimize our environmental impact due to long transport routes, but also react quickly and flexibly to your requirements.

Advantages through regional partnerships

-

Fast:

Short delivery routes enable us to react quickly to changes and orders. -

Environmentally friendly:

Reduced transportation routes reduce CO2 emissions and support our environmental goals. -

Cost-efficient:

By purchasing in the region, we reduce logistics costs and can pass these savings directly on to you.

Our close cooperation with regional partners not only ensures a reliable supply, but also strengthens the local economy and promotes sustainable practices. Together, we create an efficient and environmentally friendly supply chain.

A sustainable supply chain is of central importance to us. We are proud that many of our suppliers have their production facilities in Germany. This enables us not only to reduce our carbon footprint, but also to react flexibly to changes. This proximity to our suppliers allows us to ensure that our products are not only of high quality, but are also manufactured with ecological aspects in mind.

Through these innovative approaches, we not only improve our production processes, but also actively contribute to environmental protection and reduce our operating costs.

Michael Dickel, Head of Purchasing