Make the most of tomorrow's technology today more power for your pump

New, trendsetting motor technology with energy efficiency IE5

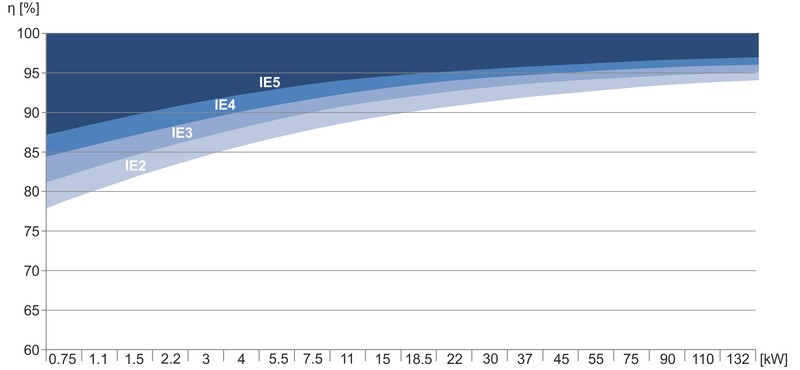

With the use of IE5 motors, Herborner Pumpentechnik is heralding a new era of energy efficiency in the world of pump technology: PM motors (permanent magnet motors) of energy class IE5 reduce the losses compared to IE4 motors by a further 20%.

The motors improve efficiency by up to 13% in the process.

More performance, less costs!

The new technology of PM motors (synchronous motors) gives you three decisive benefits:

- Greater performance through excellent levels of efficiency

- Lower operating costs due to high energy savings and thus higher profitability

- Reduced CO2 emissions due to lower power consumption

Benefit from tomorrow's technology today!

PM motors already reach efficiencies that are required in the future by law, and consistently achieve motor efficiencies that complies with the highest currently achievable efficiency class IE5.

Optimally suitable for swimming pool technology

PM motors are ideally suited for use in swimming pool technology because the frequency inverters needed to operate the PM motors are already being widely used in this field. Benefit from a more efficient, frequencyregulated and therefore process-optimised drive system for your swimming pool circulation pumps.

With the new technology, Herborner Pumpentechnik has been successful in greatly minimising drive losses.

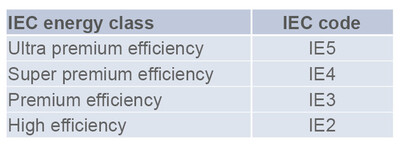

The specified efficiency standards that motors will have to comply with depending on category in accordance with the IEC code are IE3 or IE2 with frequency converter. PM motors have an efficiency of IE5!

Energy classification of electric motors

Highest efficiency: advantages compared to asynchronous motors

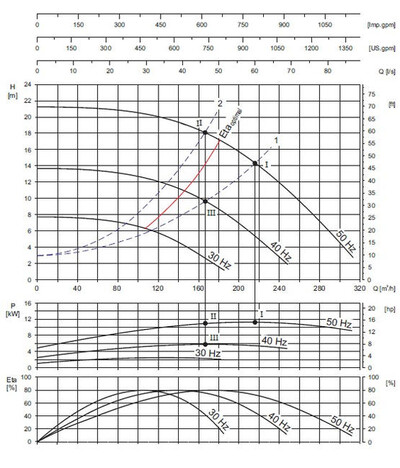

In comparison with the asynchronous motors frequently still used in swimming pool technology, the synchronous motor (PM motor) has clear advantages. This is because asynchronous motors have a lower efficiency than synchronous motors due to rotor slippage. The smaller the asynchronous motor, the higher the losses and thus the worse the efficiency. In these applications, PM motors are the optimum alternative, which is demonstrated most clearly in the night-time energy reduction in swimming pools. Thus, asynchronous motors significantly lose efficiency in speed reduction, while PM motors almost retain the efficiency advantage and thus have considerable energetic advantages over asynchronous motors.

The pump curve shown in the diagram with 3 kW drive output compares the electrical power consumption (efficiency) of the PM motor with an asynchronous motor. The PM motor has a considerably lower power consumption.

An investment that quickly pays off!

At today's high energy costs, the higher investment into this profitable technology pays off rapidly. With a pump life in swimming pool systems of 8,000 hours per year, the high investment is easily amortised in less than 1.5 years (depending on the motor power and duty point).

Contact for sales

Contact us for more information! We will be happy to explain the advantages of PM motors in a personal talk and make you an accurate quotation for your particular application.