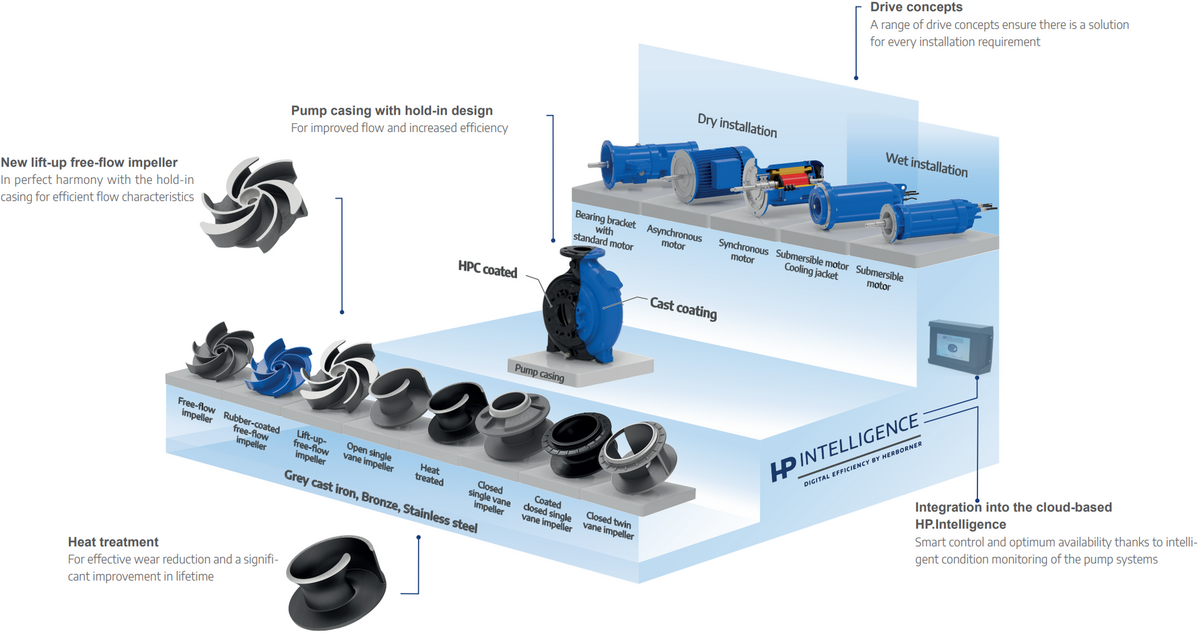

THE INNOVATIVE CENTURIO MODULAR PUMP DESIGN

The objective of series development is to meet the following requirements of the market.

Advantages

The interplay between process innovations and product innovations from the development and production departments enables new evelopments to be brought to life which provide customers with the optimum pump hydraulics for their particular requirements.

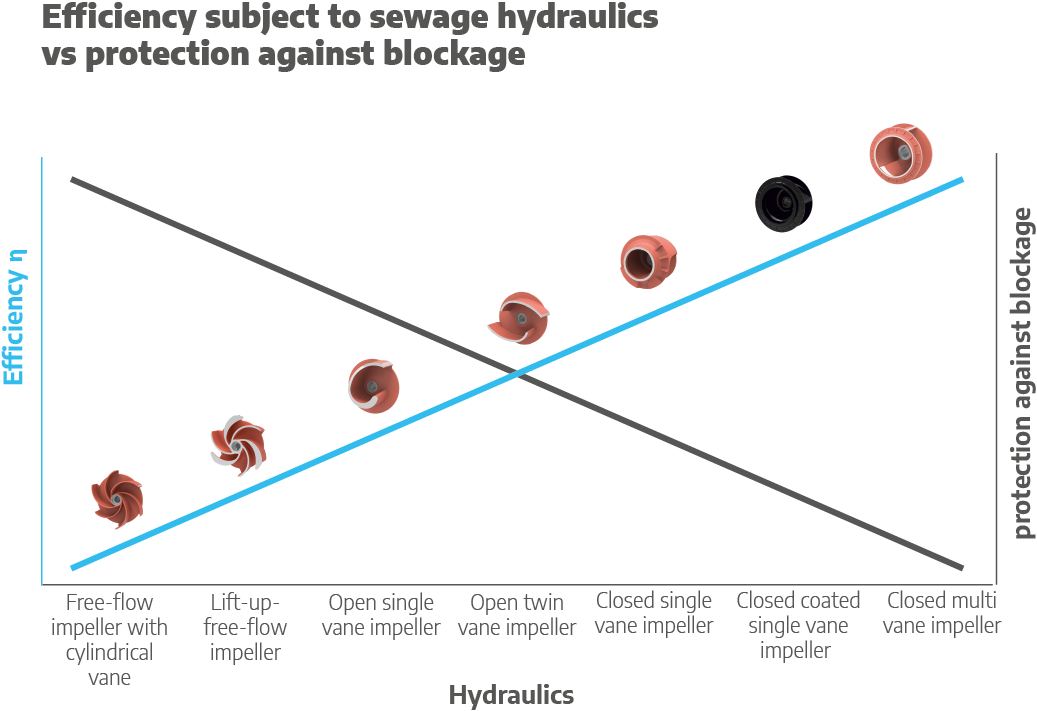

Impellers

Sewage pumps differ in terms of the wide range of impellers they feature. The type of impeller selected determines the pumping haracteristics which in turn are reflected in the efficiency of the pump.

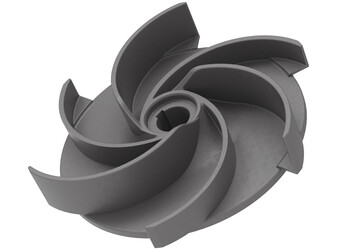

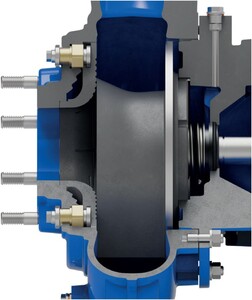

FREE-FLOW IMPELLERS – THE ALL-ROUND SOLUTION

High level of protection against blockages and resistant to abrasive and gaseous media. These impellers hold firm where all others would give in. These effects are enhanced by a special version incorporating a wearresistant rubber coating. The innovative design of the lift-up free-flow impeller also ensures a higher level of efficiency thanks to its efficient flow characteristics.

OPEN SINGLE VANE IMPELLERS – THE HARD-WEARING SOLUTION

The open single vane impellers with a non-clogging system effectively prevent unwanted blockages. The hard cast surfaces, which can be enhanced further through heat treatments, increase the lifetime of the impeller on a long-term basis.

CLOSED VANE IMPELLERS – THE EFFICIENT SOLUTION

Closed vane impellers are the ideal choice in order to achieve optimum efficiency. Depending on the medium, efficiency is additionally increased by means of our own HPC thick-film coating, which effectively prevents corrosion to the cast material and enables the medium to be pumped more smoothly.

Specials

The adjuster enables the wear plate for the open single vane impeller to be adjusted as and when required to achieve effective operation with a high level of efficiency on a long-term basis.

The proven HPC thick-layer coating is now also available for closed vane impellers used in sewage applications to provide effective protection against corrosion. In addition, the smooth surface results in fewer deposits forming as well as an increase in efficiency.

Thanks to the patent-pending innovative hold-in design, vortices in free-flow impeller pumps are effectively reduced, significantly improving flow characteristics and efficiency. This concept works in perfect harmony with the lift-up free-flow impeller which combines the advantages of free-flow impellers with enhanced efficiency.

INSTALLATION OPTIONS

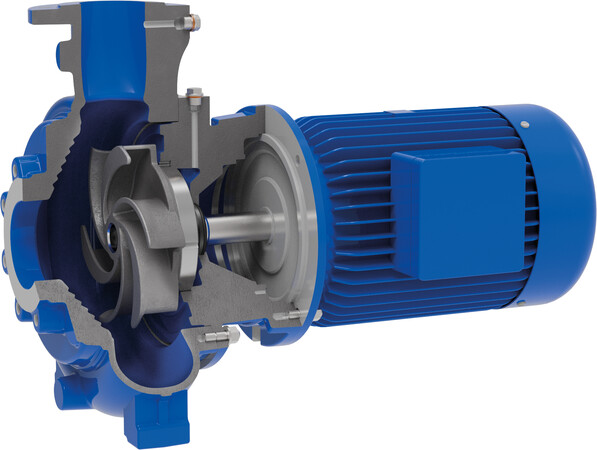

CLOSE COUPLED SEWAGE PUMPS

The widely accepted standard

Installed dry, these pumps allow inspection and maintenance work to be carried out easily, as they are easy to access and are not contaminated by the medium on the outside. Generously dimensioned shafts and bearings provide the pump with a level of durability that is reflected in longer running times and reduced lifecycle costs.

Optional versions

SUBMERSIBLE PUMPS

The amphibian pumps

This pump version normally operates submerged in the pumped medium, enabling compact pumping stations to be used. A particular feature of the submersible motors is a special cooling circulation system which enables them to also be operated as a dry installation.

Optional versions

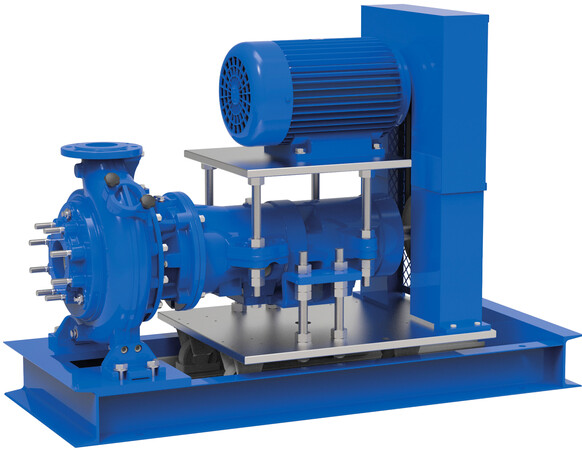

PROCESS PUMPS

The smooth and reliable solution

Equipped with a bearing bracket and standard motor, this type of construction can be connected by means of a coupling or belt drive. This heavy construction ensures that the medium is pumped smoothly and additional masses prevent surges from occurring, for example in the event of a power failure.