Heat exchanger motors Possible savings

The driving force of success is innovation

Innovation does not mean following trends; it means setting them. Throughout its long history, Herborner Pumpentechnik has been at the forefront of developing and refining pump technologies and different types of drives. Especially in regard to the constantly growing importance of energy savings, Herborner Pumpentechnik has been setting milestones for years. Our own Development department is extremely keen to experiment, which has resulted in sustainable, efficient, high-quality, practical results, especially in regard to energy efficiency.

Heat exchanger motors (C)

Equipped with a cooling jacket, medium-cooled motors are characterised by their high energy efficiency and environmental friendliness. In use, these motors work like heat exchangers.

Using water cooling, the motor can save and reuse up to 95% of the lost energy. Water is conducted around the motor through a special cooling jacket that surrounds the motor completely. The dissipating heat produced by the motor is thus collected and resupplied to the pumped water in the form of heat. In comparison with air cooled surfaces, water cooled surfaces have an approximately 100 times higher heat transfer coefficient. Water cooling thus optimally takes up the heat loss of the motor. This energy reuse principle allows considerable savings in heating costs. Heat exchanger motors also aid in making heat exchangers smaller due to heat recovery and also reduce the heating of the machine room at your place of use. The optional version in IP 67 type of protection also permits use in rooms at risk of flooding.

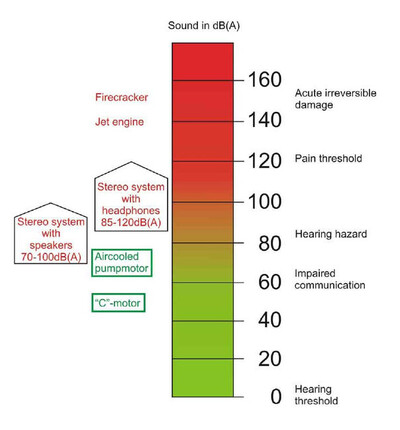

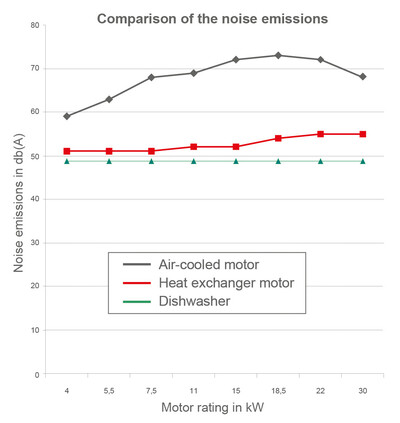

Reduction of the noise emissions for heat exchanger motors

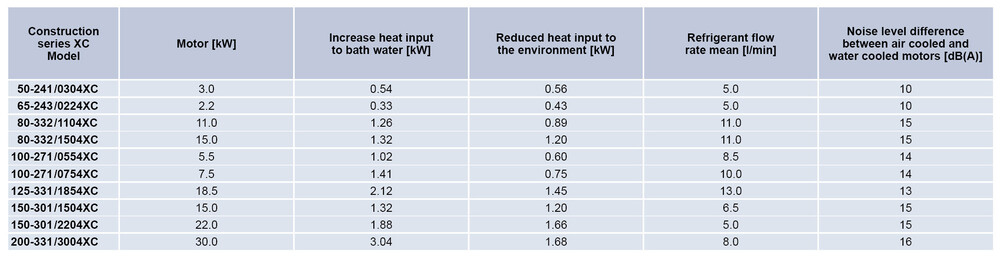

Heat exchanger motors not only save energy costs, but are also as a rule quieter by more than 10 db(A) compared to conventional air-cooled motors. This corresponds to a halving of the noise level. This makes these motors an attractive option for sensitive applications, such as in hotel systems. The following diagram shows the reduction of the noise level of a heat exchanger motor in comparison to an air cooled motor.

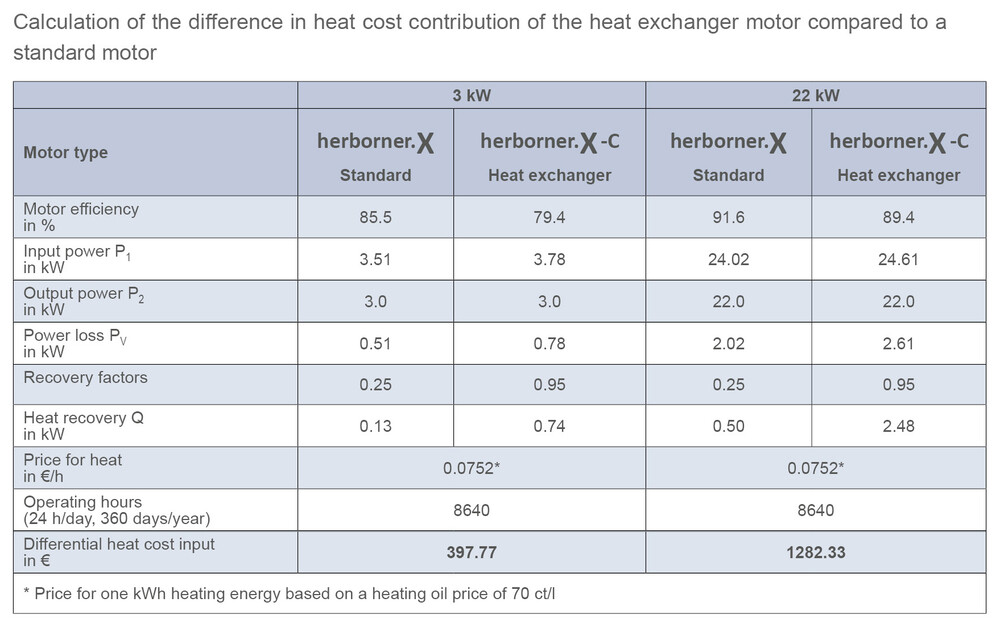

Energy saving by means of a heat exchanger motor

The following shows the possibilities of energy savings using heat exchanger motors. The heat recovery on its own allows savings between 200 and 2000 EUR per year (savings potential increases with the motor size).

Areas of application of heat exchanger motors

The areas of application of the heat exchanger motors are versatile: the following example illustrates the savings that can be realised using a heat exchanger motor as the driver of a bath water circulating pump. Bath water circulation pumps with heat exchanger motors are used to pump and filter bath water, fresh water, sea water, industrial water, and other liquids contaminated by coarse materials. According to the medium design, pumps with an integrated prefilter (herborner.X-C, UNIBAD-XC) or as block pumps (herborner.F-C, UNIBLOCK-GFC) are used. The heat exchanger motor convinces due to its low noise emissions, versatile usability, and a high degree of energy savings and cost efficiency, thus making a direct contribution to worldwide climate protection.

Savings as the driver of a bath water circulating pump

Do not hesitate to contact us! We will make you an individual offer for the optimum use of this future-looking drive concept in connection with our sophisticated pump technology.