“The more information is available, the more and better optimization can be undertaken.”

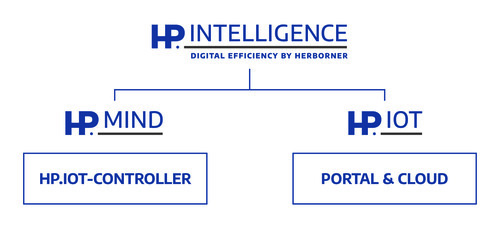

The HP.MIND hardware in the HP.INTELLIGENCE system is the key to a new, digital world of pumps. The HP.IOT controller connects the pump to the “Internet of Things” (IoT). To do this, HP.MIND collects information from the connected pumps and sends it in encrypted form to the cloud of Herborner Pumpentechnik. In the process, not only pump data are recorded, such as delivery rate, delivery head, and speed, but also various events are transmitted, such as a dry run of the mechanical seal, a short-circuit of the motor or information about the cleaning of the prefilter of the bath water circulation pump. Furthermore, the HP.IOT controller is a full-featured programmable logic controller (PLC), which enables it to completely automate smaller systems. The integration of HP.MIND in larger systems with an existing PLC can be done via the various analog and digital inputs or PROFINET RT. This significantly simplifies pump control and standardizes the interfaces.

HP.IOT portal – the central location for all information

The information can be used via the HP.IOT portal. The portal offers the possibility to receive information at any time and from anywhere in the world on each terminal device. Thus, simple questions, such as “Are my pumps still running?” and also complex jobs, such as creating energy evaluations with the goal of increasing the efficiency of the systems, can be dealt with conveniently and simply. In the future, it will also be possible to make modifications to the system directly via the portal.

HP.MIND and the HP.IOT portal together form the new digital world HP.INTELLIGENCE. This is a total solution from Herborner Pumpen that leaves nothing to be desired. Both elements of the new eco-system are optimally tuned to each other and harmonize in every respect. More smart products will be developed in the future on based on this.

The overarching goal of these developments is to help the customer operate the system as efficiently as possible. This includes, on the one hand, the optimization of operating conditions, which lower energy costs. For example, HP.MIND recognizes how the pump system and/or its pumping job can be optimized. Moreover, the increase in the accessibility of the pumps plays a central role. In addition, time-critical errors, for example a dry run, are detected directly on the HP.MIND or the on-site system in order to protect the pump. Furthermore, long-term analyses enable condition-based maintenance, so that service calls can be planned and minimized. The portal-side service calendar is used to better control the necessary work on the pumps. This is intended to afford customers an optimum view of the necessary activities, and the calendar can also be used by customers to make their own entries of jobs for the swimming pool or system operator.

The information in the HP.IOT portal is significantly more extensive than the telemetry data of the pump. As a customer, it is possible to manage all pumps in the portal. Repair reports and service calls are also documented in it. Thus, a product history is thereby created without requiring any further action. To supplement this, dynamic and thus constantly up-to-date documentation for each individual pump under observation can be called up. The further development of the service calendar into an intelligent solution later offers the possibility to assign service calls, adapted lubrication intervals and other events of the pump. In addition, the new online shop is also integrated in the system. Every user can use this to find the correct spare parts and the required accessories and order them easily.

Thus, the HP.IOT portal goes far beyond the pure visualization of cloud information. It gives answers to the most important questions about the pumps. For all questions going beyond this, the integrated ticket system offers the possibility to get help in a direct way. On request, a service can be temporarily enabled to access the system and provide a fast solution. The HP.IOT portal is the full-service package for everyone who uses a Herborner pump.

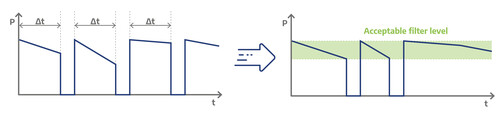

Optimization of swimming pool facilities

The new smart world of information makes various events more plannable and foreseeable. An example of this is the contamination of the prefilter of a swimming pool water circulation pump. The degree of contamination can be determined based on the pump output. Previously, it was common for the system operator to clean the prefilter in defined time intervals, regardless of the degree of contamination. HP.INTELLIGENCE makes the filter condition visible. As a result, the cleaning intervals can be adapted in line with the condition. This saves time for other work and furthermore reduces the use of chemicals, which minimizes costs.

HP.INTELLIGENCE is further proof of the innovation of Herborner Pumpen technology. The inclusion of these new technological possibilities for the customers underscores once again the future-oriented approach of the family-owned company.

Find out more about HP.INTELLIGENCE

published on 03.08.2021, Herborner Pumpentechnik GmbH & Co KG