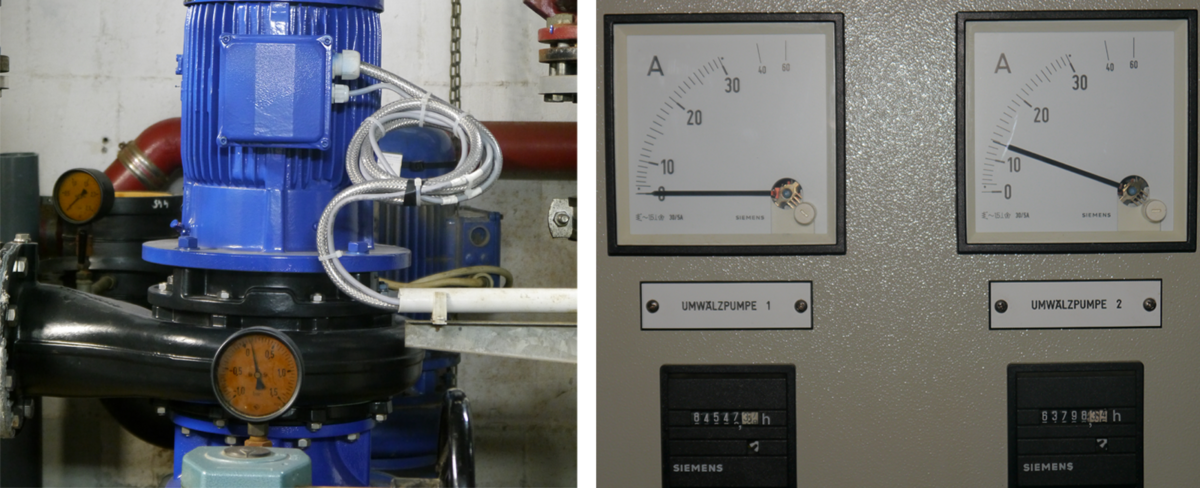

Berliner Bäder Betriebe (BBB) [Berlin pools operations] stand for several superlatives at once. They are the largest pool operator in Europe, and also have the largest swimming centre on the continent in their portfolio, with the swimming and diving pool in Europasportpark. Overall, BBB operate more than 60 indoor swimming pools, beach and summer pools in the capital city. To operate these pools, around 8,500 pumps are being used, including 500 for water treatment. The majority of these pumps are products of the Herborner Pumpentechnik.

Wolfram Kaube, Head of the Construction and Technology department of BBB, has always had good experiences with the pumps from Herborn. “They have a long service life, are reliable and low-maintenance”, says the swimming pool expert known even beyond the boundaries of Berlin. Due to his satisfaction with the UNIBAD pumps used until now, Kaube initially showed little interest, when his contact person at the Herborner Pumpentechnik, Gerd Gomoll, introduced a coated pool water circulation pump in spring 2014, with the new series herborner.X. This new generation of pumps has new pump hydraulics, which have a significantly higher level of efficiency, due to the coating and the extremely smooth accompanying surfaces. In connection with a permanent magnet motor, the energy saving is also increased for the operator. “Many parameters are only achieved on the test benches of the pump manufacturers, but not in real operation”, says Kaube in justification of his reticence at the time. Convinced of their product, Herborner Pumpentechnik offered BBB a field test.