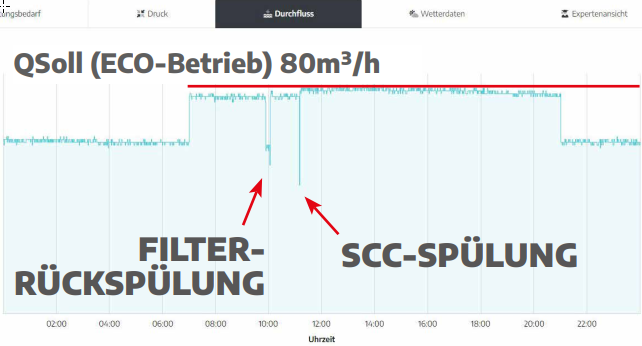

Automated cleaning of the filter baskets based on the actual degree of soiling significantly reduces the time and labour required. The circulation volume is maintained in accordance with the standard specifications and any deviations in the pump characteristic curve can be recognised at an early stage using the cloud data. While maintaining constant flow control, this also leads to considerable savings in energy costs due to the reduced back pressure. In addition, the SCC system integrates the ETSPro, which independently deaerates the pumps, again minimising the time required and potential downtime costs due to dry runs.

Following the extensive test phase, the quality of the automatic cleaning processes received a consistently positive assessment and manual cleaning of the filter baskets is now only necessary in isolated extreme situations.

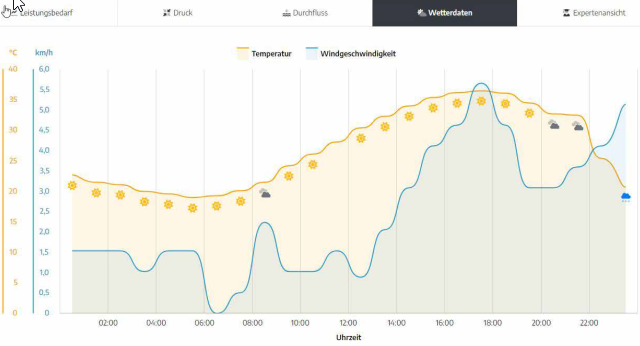

After analysing operating and weather data, we plan to further develop the cleaning intelligence and the algorithms used. So far, the SCC system has been recommended as the optimum solution for outdoor pools, especially in heavily greened facilities.

In indoor swimming pools, the evaluation of operating data by an HP.Mind controller contributes to failure-avoiding monitoring of the pumps and pre-filter baskets even without the SCC system.